What is Ducting? A Guide

Have you been told you need to install ducting, but aren’t really sure why or what kind you need? Or, are you looking to brush up on what this essential equipment is? If so, you’re in the right place. In this guide from the team at The Hosemaster, we’ll take you through the ins and outs of ducting; including what it is and why it’s important for multiple industries.

So, keep reading for more information about ducting...

What is ducting?

First things first, what is ducting?

Ducting is the general term used to describe a network of pipes and tubes found within a building or industrial area to direct air, fumes, dust, or other harmful and/or abrasive materials from one place to another. These are essential for multiple reasons; for example, to keep the air quality at a safe level by removing irritants; or to maintain air temperature within a home or commercial environment.

Is there a difference between ducting and hoses?

Whenever ducting comes up, one question that typically follows is about the difference between ducting and hoses. After all, both are cylindrical tubes that allow for the movement of materials.

However, the primary difference is the type of materials that pass through them both. Hosing is typically narrower, and primarily used to transport liquids from one system to another. This is because their smaller diameter allows them to generate the pressure required to keep liquids flowing smoothly.

Ducting on the other hand, has a wider diameter, and typically deals with the movement of gases and/or airborne small particles - like dust and sawdust.

What is ducting used for?

As we mentioned above, ducting has many uses across a variety of industries and locations, including, but not limited to:

- Construction: ducting can remove harmful fumes and dust from the air for a safer working environment.

- Air conditioning: ducting is responsible for moving cool, heated, or filtered air throughout a HVAC system.

- Ventilation: ducting can be used by ventilation and extraction systems to move gases - like steam from cooking.

- Woodworking: using ducting is an easier way to collect and manage dust and sawdust generated during woodwork.

- Factories: factories use ducting to remove harmful solvents, oil mists, and other fumes to protect their workers and the air quality.

- Agriculture: ducting can reduce the build-up of condensation in agricultural settings, or help move small pellets and grains from one location to another.

Remember, ducting can be found in commercial, industrial, and domestic settings.

Why is ducting important?

Ducting pipes are vital for many reasons. For example, HVAC (heating, ventilation and air conditioning) units use ducting within domestic and commercial properties to supply hot and cold air to create a comfortable living environment.

Alternatively, ducting is used to help remove dangerous fumes and keep air quality at a clear and safe level. For example, when various chemicals or oils are used within an industrial environment, ducting can help to ventilate the space and keep you safe.

Ducting networks can also act as an outlet to remove exhaust fumes whilst machinery is working, reducing the risks of internal pollution within a factory or warehouse.

Top tip - efficiently designed and functioning ducting networks can save you a lot of money and energy over time.

Ducting networks allow for air or small particles to be funnelled into new locations easily, saving you time, energy, and money.

Active and passive ducting

The majority of ducts are described as passive because they have no moving parts - gases move through them without the use of additional materials. For example, air can pass through ventilation systems from inside to outside due to differences in pressure rather than an external force moving it (like with active ducting).

Alternatively, a ducting network may use active methods to transfer materials with more pace, or when power is required to shift small pellets or other particles. These are typically powered by a motorised fan within the system. Vacuum ducts, extractor fans and air conditioning units are all examples of active ducting.

Rigid or flexible ducting

Another important aspect of ducting is deciding whether you need rigid or flexible ducting pipes. Flexible ducting pipes usually come in coils, and can be positioned at different angles (as long as you don’t obstruct the internal diameter too much). This is perfect for more awkward networks, or when you need to fit your ducting to a space. They’re also much easier and cheaper to install.

On the other hand, rigid ducting pipes cannot be shaped easily - and are usually made of metal or other inelastic materials. Rigid ducting is usually more durable because of this, and is easier to clean, and keep clean, as the smooth surface discourages mould or other pollutants from settling.

Types of ducting pipes

Of course, you can’t just use any type of ducting pipe and expect it to perform the function you assign it. Each situation or ducting network will require the appropriate type of ducting pipe to ensure there is a minimal risk of damage - and to ensure you get the most for your money with each application.

Temperature, material, and location are all essential environmental factors that will affect how your ducting performs (both in terms of efficiency and durability), and will dictate the type of ducting pipe you need.

Top tip - using the appropriate type of ducting is safer, more energy efficient, and more cost-effective in the long run.

Aluminium laminate ducting

Aluminium laminate ducting is ideal for air conditioning applications because it can minimise heat loss or gain to ensure your system is running efficiently.

Laminated aluminium foil and woven polyester is durable, and can be reinforced with a steel spiral. This allows for maximum flexibility, meaning you can install it easily into a system without disrupting the surrounding areas. With a high temperature rating (up to around 125℃), this type of ducting pipe is safe to use within a HVAC system to heat a home.

Buy Now - Aluminium Laminate Ducting

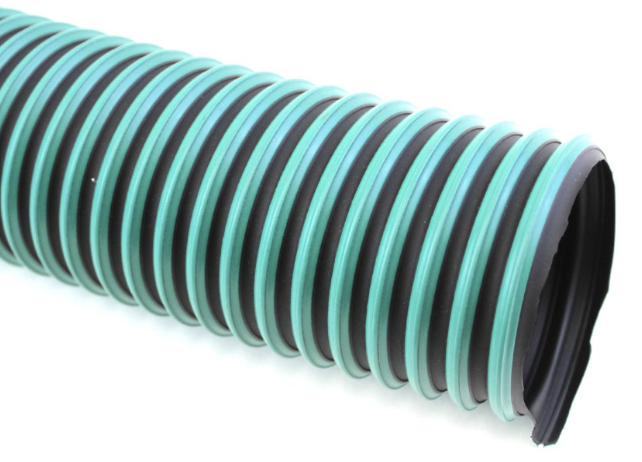

Polyurethane ducting

Polyurethane is a type of synthetic elastomer, which is a classification of materials renowned for being durable, flexible, and elastic. These materials have been used across a wide range of applications, but they’re frequently used to make ducting pipes of varying grades and thicknesses.

Polyurethane ducting works best below 90℃, however it can be used intermittently in higher temperatures. Whilst it doesn't typically melt at higher temperatures, it can degrade - so it’s important to use polyurethane ducting appropriately. On the flip side, polyurethane is flame retardant, which can help prevent the spread of fires within your ducting network.

At The Hosemaster, we have four main types of polyurethane ducting you could choose from depending on your needs. These are:

- Light polyurethane: this is made from a 0.4mm polyurethane tube, with a copper coated steel wire spiral that provides structural support. This type of ducting is ideal for extracting dust during woodworking, or moving air throughout a system.

- Medium polyurethane: moving through the scale, our medium polyurethane ducting is 0.7mm thick for a stronger exterior - and is also supported by copper coated steel spiral. The thicker polyurethane walls mean that this ducting can be used for more heavy-duty applications, like suction and delivery of dust, powders, fibres and small pellets.

- Heavy polyurethane: our heavy polyurethane ducting pipes are 1mm thick, with support provided by a copper coated steel wire spiral. The thicker walls of this ducting make it more resistant to abrasive materials, and allow you to move grain, animal feed, woodchip, and other larger particles from one place to another.

- Superflex polyurethane: the superflex polyurethane ducting pipe ranges from 0.4mm-0.8mm, and has a strong but flexible PVC spiral with anti-shock capabilities to improve the stability and durability of your ducting network. This is ideal for moving liquids, or dry foods like grain, animal feed, sugar and flour.

Neoprene ducting

When most people think of neoprene, they think of wetsuits or wet shoes. However, this flexible synthetic rubber can make an excellent ducting material.

Buy Now - Wyreflex Neoprene Fabric Ducting

Neoprene is highly flexible, which means it’s relatively easy to install this type of ducting. Neoprene is also heat-resistant, and instead of melting will tend to stiffen. Whilst this can be safer from a certain perspective, it does mean you need to make sure your system doesn’t overheat and affect the flexibility of your ducting.

Plus, neoprene is highly chemically-resistant, which makes it suitable for industrial ducting - particularly in the transfer of oil mists and harmful fumes.

Silicone ducting

Silicone is a fantastic material that can be put to a variety of uses - including ducting pipes. This is because silicone is durable, flexible, and able to withstand high temperatures without melting or warping.

Buy Now - VULCAN Heat-Resistant Silicone Ducting

Silicone ducting is often used in high temperature but low pressure applications; like steam vents in washing machines, exhaust systems, or industrial ovens; and to vent toxic chemical or solvent gases.

Thermoplastic ducting

Thermoplastics are a highly durable synthetic material that takes some of the best characteristics from plastic and rubber. With a high level of elasticity, this type of ducting is very lightweight and flexible - making it relatively easy to install.

The steel wire internal spiral provides plenty of structural support to ensure that your ducting network can withstand the years, and work efficiently where you need it to.

Buy Now - TPRA Two Ply Thermoplastic Rubber Ducting

Thermoplastic ducting is also useful for applications like fume ventilation and removing toxic materials due to its high chemical resistance. As well as this, it’s also heat-resistant, which makes it good for exhausts and moving hot air through a network.

Top tip - multipurpose thermoplastic ducting is often used for mechanical applications, like engine air intake, brake cooling systems, and mechanical ventilation.

PVC ducting

PVC, or polyvinyl chloride, is one of the most commonly made plastics in the world, and can come in rigid or flexible forms. PVC ducting uses the flexible form of PVC to great effect, offering you a durable, reliable ducting pipe that’s perfect for lightweight air extraction.

For example, PVC ducting can be used alongside domestic washing machines and dryers to ventilate the air during and after use. PVC ducting can also be used for other air conditioning purposes, like ventilating fumes under light pressure.

Note - PVC ducting can distort under high temperatures, so make sure your intended use is appropriate for the material.

Find the best range of ducting pipes at The Hosemaster

If you’re looking for an excellent range of ducting, you’ve come to the right place. At The Hosemaster, we have decades of experience within the hose and ducting supplies industry, and can use this to help you throughout your buying journey and beyond.

Our friendly team of experts are always on hand to answer any questions, or offer you buying advice. Simply give us a call on 01282 604 002 to speak to a member of our team. Prefer communicating online? Get in touch with any enquiries through our website.

Shop for ducting pipes today from The Hosemaster

For more information, buying guides, and useful advice, check out The Hosemaster blog today…

What Are Quick Release Couplings? | How to Check Tyre Pressure and Inflate Your Tyres | A Guide to Grease Guns and Grease Nipples

French

French German

German